- Home Page

- Company Profile

-

Our Products

- Hydrocyclone

- Custom Moulding Roller Cover

- Polyurethane Mallets

- Polyurethane Liner

- Polyurethane Screen

- Screen Panels

- PU Modular Screen

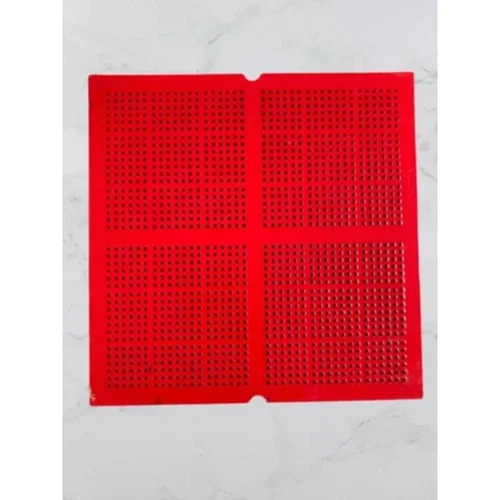

- Flip Flop Screen Mats

- 70 mm Polyurethane Screen panel

- PU Screen Panel -610mmX300mmX30THK

- Polyurethane Screen panel

- Dewatering Screen panel

- Perforated PU Screens

- 90 mm Mining Equipment Polyurethane Screen

- Black Mining Equipment Polyurethane Screen

- Polyurethane Screen Panel

- Mining Process Equipment Polyurethane Screen

- Mining Screen Panel

- 60 mm Mining Equipment Polyurethane Screen

- Urethane Screen Panels

- High Frequency Screens

- Red Mining Equipment Polyurethane Screen

- Yellow PU Screen- 900mm x 300 mm X 30mmTHK

- Screen Panel Leg type

- Pin Type Fixing Screen

- Mine Screen Panel-610mmX300mmX30THK

- Diamond Mining Equipment Polyurethane Screen

- 70 mm Mining Equipment Polyurethane Screen

- Press Fit Screens

- PU Screen Panel

- Polyurethane Screen Mesh

- Polyurethane Screen Panel-305mmX305mmX30THK

- PU Vibrating Screen

- PU Coal Screens

- Circular Vibratory Screen

- Polyurethane Screen Panel

- Mining Accessories-Polyurethane Screen

- Vibrating Screen Mesh

- Vibrating Wire Mesh Screen

- Polyurethane Screen Panel

- 80 mm Mining Equipment Polyurethane Screen

- PU Screen Mat

- Mining Equipment Polyurethane Screen

- Press Fit Modular

- Vibro Screen Machine

- 50 mm Mining Equipment Polyurethane Scree Panel

- Modular Deck Press Fit Type Screen

- Industrial Vibratory Screen

- PU Bucket Screen Deck

- Industrail Vibrator Screen

- 2 Deck Vibrator Screen

- Dewatering Screen Separators

- Polyurethane Screen Panel

- Polyurethane Dewatering Screen

- Mining Accessories-PU Mining Equipment Screen

- Mining Accessories-PU Screen Panel

- Mining Rubber Screens

- Rubber Screen Panels

- Perforated Screen Plate

- PU Rotary Screen

- Screening Mining Screen

- Vibrating Screen Deck Panels

- Fine Screen mat

- Material Sifting Screens

- Mining Trommel Screen

- Polyurethane Tubes

- Polyurethane Rods

- Polyurethane Wheels

- Polyurethane Sheets

- Polyurethane Vibratory Bowl

- Polyurethane Rollers

- PU Coated Roller

- Flanged Rollers With Bearing

- Heavy Duty Rollers

- Industrial Conveyor Rollers

- PU Conveyor Rollers

- Polymer Guide Roller

- 600 mm Polyurethane Rubber Roller

- Polyurethane Load Rollers

- PU Guide Rollers

- Steel Plant Roller

- 300 mm PU Rubber Roller

- Carrying Rollers-Idler carrying roller

- Top Pinch Roller 500mmX1750mmL

- Bottom Pinch Roller -500mm X1750mmLength

- Carrying Rollers -PU Rubber Conveyor Roller

- Carrying Rollers-Conveyor Roller

- Carrying Rollers -Carrying Roller

- Carrying Rollers-Conveyor Idle Roller

- Pinch Roller- SL Middle Pinch Roller

- Pinch Roller-Pinch Roll-265X230X1425

- Pinch Roller-Roll Pinch-1760mmL

- Heavy Duty Roller Castors

- Polyurethane Coating On Roller

- 80 mm Polyurethane Roller

- Conveyor Polyurethane Roller

- Polyurethane Brush Rollers

- Rubber Ink Roller

- Polyurethane Bridle Roller

- Polyurethane Boat Roller

- Polyurethane Roller Coating

- Industrial PU Rollers

- 350 Mm Polyurethane Rubber Roller

- V Groove Wheels

- PU Pipe Rollers

- Polyurethane Printing Roller

- Polyurethane Coated Roller On MS Pipe

- 500 Mm Polyurethane Rubber Roller

- Polyurethane Conveyor Roller

- Polyurethane Lining Rollers

- PU Coating Printing Rollers

- Polyurethane Covered Rollers

- 150 Mm Polyurethane Rubber Roller

- 400 mm Polyurethane Conveyor Roller

- Urethane Coated Roller

- 800 Mm Polyurethane Rubber Roller

- 700 Mm Polyurethane Rubber Roller

- 400 Mm Polyurethane Rubber Roller

- Printing Polyurethane Rollers

- PU Conveyor Roller

- Polyurethane Pad-Happy Pad-1950X100X10mmTHK

- Pinch Roller-Chequered Finish Roll

- PU Ink Rollers

- Sliding Window Roller

- Polyurethane Rubber Roller

- 300 Mm Polyurethane Rubber Roller

- 200 Mm Polyurethane Rubber Roller

- Polyurethane Feed Rollers

- Polyurethane Rubber Roller

- 500 mm Polyurethane Conveyor Roller

- PU Pallet Rollers

- PU Rubber Roller

- PU Coating Rollers

- Polyurethane Pulley Rollers

- PU Coverings Roller

- PU Coated Gravity Roller

- Silicone Polyurethane Rollers

- Polyurethane Rubber Roller

- PU Printing Roller

- Urethane Coated Roller

- Polyurethane Coated Roller On MS Pipe

- PU Drive Roller

- Track PU Rollers

- Hot Ink Rollers

- Ball Bearing Rollers

- Ball Bearing Rollers -PU Roller with Bearing

- Ball Bearing Rollers-PU Roller with Ball Bearing

- Hot Ink Rollers-Ink Tranfer Roller

- Hot Ink Rollers-PU Ink Transfer Roller

- Tension Leveller -Industrial Tension Leveller Roll

- PU Track Roller

- PU Drive Rollers

- Neoprene Rubber Roller

- 3m Squeeze Roller -1750mmL

- Ball Bearing Rollers-Ball Bearing Roller

- Ball Bearing Rollers -PU Ball Bearing Roller

- Ball Bearing Rollers-PU Bearing Roller

- Neoprene Rollers With Bearing

- Bridle Rolls-Hold Down Rolller

- Grooved Rollers-V Groove Roller

- PU Taper Roller

- Polyurethane Liners Rolls

- Industrial Rollers

- Tapered Conveyor Rollers

- Tapered Industrial Rollers

- Metal Guide Rollers

- 400 mm Guide Roll

- Stainless Steel Roller

- Polyurethane Conveyor roller-190X40X66

- Pressure Roller-Pressure Conveyor roller-120mmX70mmX800mmL

- Rubber Roller- Silicon

- Plastic Conveyor Roller -PU Belt Conveyor Roller

- Hot Ink Rollers -Printing Roller

- Carrying Rollers-Polyurethane Conveyor Roller

- Carrying Rollers-PU Conveyor Roller

- PU Roller -Nylon Conveyor Roller

- SS Gravity Roller

- Carrying Rollers-Heavy duty conveyor Idler roller

- Industrial Steel Roller

- Gravity Roller Conveyor

- Printing Rubber Roller

- PU GUIDE ROLLER-200X168X1800mmL

- INDUSRIAL GUIDE ROLLER-162X42.5X78

- Printing Rollers- Ink Rubber Roller

- Wringer Roller -3M Roller -255X150X1527mmL

- Taper Roller-PU Taper Roller-302X242X690

- Rubber Roller -Hypalon

- Industrial Metal Roller

- Pinch Rolls-195mmX165mm X1500mmL

- Rubber Roller for Nitrile

- Wringer Roller -Squzee Roller

- Wringer Roller-Non Woven Roller

- Hot Ink Rollers -Ink Roller

- Contact Us

Flip Flop Screen Mats

5400.00 INR/Piece

Product Details:

- Classification Industrial Sieving Equipment

- Grade Industrial Grade

- Application Mining, Aggregate, Sand, Coal Screening, Quarrying

- Color Black

- Form Mat / Sheet

- Size Custom sizes available

- Material Polyurethane / Rubber

- Click to view more

X

Flip Flop Screen Mats Price And Quantity

- 5400.00 INR/Piece

- 1 Number

- Modular fixing system

- Up to 80°C (varies by material)

- Oscillating Flip Flow Screens

- Smooth or patterned as per requirement

- 2 mm to 120 mm

Flip Flop Screen Mats Product Specifications

- Industrial Sieving Equipment

- Polyurethane / Rubber

- Mining, Aggregate, Sand, Coal Screening, Quarrying

- Black

- Industrial Grade

- Mat / Sheet

- Custom sizes available

- Modular fixing system

- Up to 80°C (varies by material)

- Oscillating Flip Flow Screens

- Smooth or patterned as per requirement

- 2 mm to 120 mm

Flip Flop Screen Mats Trade Information

- 1000 Number Per Day

- 5 Days

Product Description

Shop Now for Flip Flop Screen Matsan unrivaled solution designed for demanding industrial sieving. These industrial-grade mats, available in custom sizes, feature a virtuosic installation through a modular fixing system. Perfect for mining, aggregate, sand, and coal screening, their aperture ranges from 2 mm to 120 mm, accommodating specific project needs. The mats, crafted from polyurethane or rubber, deliver smooth or patterned finishes, withstand temperatures up to 80C (depending on material), and provide steadfast performance. Add to Cart to secure the in-demand choice for oscillating flip flow screens, engineered by Indias leading manufacturer, exporter, and supplier.

Optimized Performance Across Applications

Flip Flop Screen Mats excel in mining, aggregate, sand, coal screening, and quarrying, making them ideal for heavy-duty industrial environments. Their unrivaled modular system ensures virtuoso operational efficiency and quick changeover on oscillating flip flow screens. The mats custom sizing and surface finish flexibility provide a perfect fit for varied applications, setting them apart in industrial sieving. Their superior material quality ensures longevity and reliability under intense conditions.

Packaging, Samples, and Market Reach

Each mat is securely packaged to facilitate safe Exchange across locations. Sample availability allows stakeholders to evaluate suitability before Order Completion, helping minimize expenditure risk. The mats are primarily distributed within India, supporting robust main domestic market coverage. Reliable packaging and sample policies guarantee efficient delivery and customer satisfaction from manufacturer to end-user, streamlining every transaction in demanding industries.

Optimized Performance Across Applications

Flip Flop Screen Mats excel in mining, aggregate, sand, coal screening, and quarrying, making them ideal for heavy-duty industrial environments. Their unrivaled modular system ensures virtuoso operational efficiency and quick changeover on oscillating flip flow screens. The mats custom sizing and surface finish flexibility provide a perfect fit for varied applications, setting them apart in industrial sieving. Their superior material quality ensures longevity and reliability under intense conditions.

Packaging, Samples, and Market Reach

Each mat is securely packaged to facilitate safe Exchange across locations. Sample availability allows stakeholders to evaluate suitability before Order Completion, helping minimize expenditure risk. The mats are primarily distributed within India, supporting robust main domestic market coverage. Reliable packaging and sample policies guarantee efficient delivery and customer satisfaction from manufacturer to end-user, streamlining every transaction in demanding industries.

FAQs of Flip Flop Screen Mats:

Q: How do I install the Flip Flop Screen Mats?

A: Flip Flop Screen Mats feature a modular fixing system, allowing for rapid and secure installation on oscillating flip flow screens without extensive downtime or specialized tools.Q: What applications are Flip Flop Screen Mats suited for?

A: These mats are expertly designed for mining, aggregate, sand, coal screening, and quarrying industries, making them versatile for different types of industrial sieving requirements.Q: Where can I obtain samples before placing a bulk order?

A: Sample policies are available to help stakeholders evaluate the products suitability. Reach out to the manufacturer, exporter, or supplier based in India to request product samples.Q: When does the temperature resistance vary for these mats?

A: The mats temperature resistanceup to 80Cdepends on the chosen material. Polyurethane and rubber offer distinct heat tolerance levels based on your industrial specifications.Q: What is the benefit of custom sizing for Flip Flop Screen Mats?

A: Custom sizing ensures a perfect fit for any screening equipment, maximizing efficiency and minimizing operational expenditure by reducing misfits and wastage.Q: How does the surface finish affect the mats usage?

A: Surface finishes, whether smooth or patterned, can be tailored to your requirements, optimizing material flow and screening efficiency based on specific industrial processes.Q: What is the process for exchanging or returning mats post-order completion?

A: Exchange and return policies vary by manufacturer or supplier, but secure packaging and reliable logistics streamline any necessary product exchange after order completion.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese